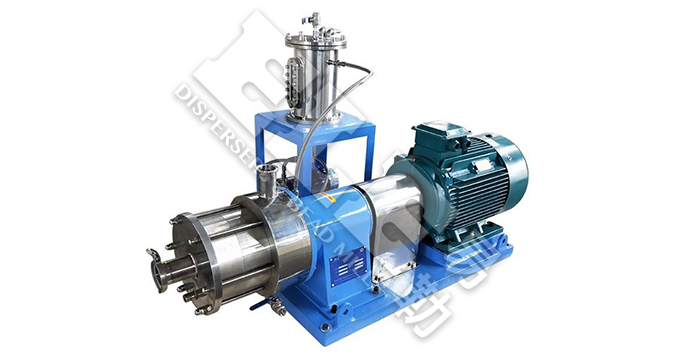

ELR Series Homogenizer Pump

ELE 26 years focusing on the industry, with the effort to keep improving and upgrading, the machine technique is very mature and quality is very stable.

With ELE's machines the homogenizing efficiency and effect get improved, use less processing time to get a more stable and longer emulsified product.

To use the best price to buy the highest level of quality and efficiency of product, which could be the most satified purchasing experience for customers.

ELE homogenizing pump includes two types:

Single stage homogenizing pump

Three stages homogenizing pump

Data Sheet & Models

|

Model

|

Power(kw)

|

Rotation Speed(rpm)

|

Flow(m3/h)

|

Entrance

(mm)

|

Exit

(mm)

|

|

ELR401/3

|

1.1/1.5

|

3000

|

0.5

|

DN40

|

DN32

|

|

ELR405/3

|

4

|

3000

|

2

|

DN40

|

DN32

|

|

ELR410/3

|

7.5

|

3000

|

4

|

DN50

|

DN40

|

|

ELR415/3

|

11

|

3000

|

6

|

DN60

|

DN50

|

|

ELR420/3

|

15

|

3000

|

12

|

DN60

|

DN50

|

|

ELR425/3

|

18.5

|

1500/3000

|

16

|

DN60

|

DN50

|

|

ELR430/3

|

22

|

1500/3000

|

18

|

DN60

|

DN50

|

|

ELR450/3

|

37

|

1500

|

26

|

DN100

|

DN80

|

|

ELR460/3

|

45

|

1500

|

30

|

DN125

|

DN100

|

|

ELR475/3

|

55

|

1500

|

32

|

DN125

|

DN100

|

|

ELR490/3

|

75

|

1500

|

45

|

DN125

|

DN100

|

|

ELR510/3

|

90

|

1500

|

55

|

DN125

|

DN100

|

|

ELR530/3

|

110

|

1500

|

70

|

DN150

|

DN125

|

ELE: Your Professional High Shear Homogenizer Manufacturer

Over 25 Years Manufacturing Experience

Shanghai ELE, with R&D, factory, global sales, engineers and market together, is largest manufacturer of High Shear Homogenizer located over more years.

ELE machine is manufactured by precision grinder machine, lathe machines, boring machine, polishing machine, drilling machine, rolling machine, milling machines, CNC machines.

With around 25 years rich experienced engineers in this area, ELE strictly control the every single process from raw material to processing, to assembling to final products testing. Strictly control the accuracy during processing.

· The grinding cavity is consists of three groups of stator and rotor (2 layers, 4 layers and 6 layers), highly working accuracy, large capacity and wide viscosity, more suitble for industrial on-line production.

· High shear emulsion pump is best emulsifying effect and top efficiency, more suitable for production which need high requirement for emulsifying, then it is the first choice for the micro-emuslion production.

· According to your PH, there are materials of ss304 and 316L for your choice.

· Adopting double mechanicial seal also can configure water protector

· It is elastic connection, low noisy and table performance.

· It can design jacket for cooling and heating.

ELE® Company has been certified by the society by virtue of its excellent quality and excellent performance in the industry .

ELE has obtained CE ,SGS ,TUV Certification, also support other third-party by ISO,BV ... ELE is the only manufacturer who has its own mechanical seal patent in Shanghai. Patent No.: 201610459850.7

We have received high praise from many customers from Asia, Europe, Africa, and north and south America, that ELE homogenizer has a better homogenizing effect and efficiency, the material after processing no seperation and sediment.

Quality Control

1、We start from the screening of raw materials for machine production. All carbon steel bodies, stainless steel main working bodies and other accessories are from famous iron and steel foundries in China. Each batch of raw materials is supplied with material test report, and the composition of carbon steel must meet the requirements of American Standard 1045 and din C45. Stainless steel must meet the requirements of American Standard ASTM a240 and Din1.4301 (x5crni18-10).

2、 Each step of cutting, grinding, stamping, bending, punching and welding has ELE drawing specifications. ELE company has high-precision machine tools, each operator has more than 15 years of experience. The machining standard center of each part has its own characteristics, especially in the plane. In the process of crankshaft machining, the accuracy is strictly controlled within plus or minus 0.01mm. In order to reduce the possibility of liquid leakage, we almost all use chamfer welding. This also Indirectly makes our processing cost is higher than that of most of our peers.

3、 We have special personnel to monitor and inspect all production links. Once any non-standard or unqualified products are found, they will be reworked or scrapped at the first time. Prevent it from flowing into the next link and affecting the quality of final products.

Efficient service ability

1.Before order, customer can take materials to our lab and make test grindings, spot-testing parameters

like particle size distribution, obtain reliable data for model selection;

2.We provide you opeatian manual by chinese or English;

3.We offer you Videos for equipment installation and maintenance in both English and Chinese;

4.With three years of spare parts inventory to ensure normal use and make you to be in trouble free;

5.Within 12-months warranty period, we promise to change damaged parts free of charge by air or by sea;

6.After delivery, our professional engineer will offer on-site guidance debugging free of charge, according to different characteristic of materials, to set up the operational parameters of the mill and ensure optimal grinding quality & equipment running status;

7.After the warranty period, we provide maintenance and maintenance service, only charge the cost;

8.Meanwhile, our skillful grinding experts can offer you free professional technical consulting and service.

Homogenizer Pump: The Ultimate FAQ Guide

What is Inline Homogenizer Pump?

The inline homogenizer pump is a high speed and high efficiency emulsifying machine for continuous production or circulating processing of fine materials. It has a precision combination of rotary and stator, which cause strong shear forces in high speed rotation to achieve mixing, homogenizing, dispersing and crushing.

What is the Working Principle of the Inline Homogenization Pump?

The motor drives the rotor to operate at high speed, and the particle size of liquid-liquid and solid-liquid materials becomes narrower through the action of external mechanical forces, so that one phase is evenly distributed into another or more phases, so as to achieve the effect of refinement, homogenization, dispersion and emulsification, so as to form a stable emulsion state.

What Are the Application Ranges of Inline Homogenizing Pumps?

Homogenizer pump can be used for continuous emulsification or dispersion of multi-phase liquid media, and at the same time for low viscosity of the liquid media play a role in conveying. It can also achieve continuous mixing of powder&liquid according to the proportion . It widely is used in daily chemical, food, medicine, chemical, petroleum, coating, nanomaterials and other fields

How Does the Inline Homogenization Pump Work?

Single-stage homogenization pump

Single-stage homogenization pump consists of one group rotor and stator( three layers of rotor and three layers of stator). The stator is fixed, when rotor driven by motor works at high speed , rotor and stator working like a pair of scissors generates high shear force to make liquid-liquid and liquid- powder particle size smaller and finely chopped, then to get evenly and stable emulsion finally.

Three-stage homogenization pump

Three stage homogenization pump consists of three groups of rotor and stator ( two layers, four layers, six layers respectively). When material enters the grinding chamber, it will be cut to small particle size by strong high shear force step by step, then reach to ultra-fine emulsification effect finally. Three-stage homogenization pump can be used in a production line to do pre-mixing of several phases liquid or to do recycling emulsification of liquid-liquid and liquid-powder material.

How to Verify the Reliability of the Inline Homogenizing Pump?

Homogenizing pump manufacturing is a complicated process and require high-accuracy of every small aspect. ELE machine can be verified reliability from following samll aspects:

Rotor and Stator

Accuracy: the rotor stator gap accuracy is in accordance with American standard,

controlled between 10-15 wires. Why is this range? If larger than 15 wires, emulsification effect can't reach the best and the only function of rotor stator is stirring rather than shearing. If less than 10 wires, the rotor stator will generate too much heat, make wear resistance damage become strong, and does no good to machine service life at all.

Material and process tech: the rotor stator is fine-forging, linear cut forming, claw-structure, two-way suction, no dead corner, high shear force to make particle size smaller.

Main shaft

The shaft is made of 45# steel with high chrome plated, after five precision process to strengthen its hardness and ensure its reliability when rotating at high speed and load with heavy material. Five processes are : molding by lathe -first finening( to adjust accuracy)-high chrome plated(to improve hardness and not easy to get rust) - secondary finening (to ensure the front part and latter part of shaft accuracy no more than 3 wires) - dynamic and static balance test(to ensure stability and reduce its runout when rotating at high speed.)

Bearing

Bearing is imported from Japan NSK , and the bearing house is an intergral part processed by digital grinder machine with high-accuracy. With professional techn, we can make bearing, shaft and pulley in an circle to make sure its accuracy. When rotating at high speed , high-accuracy will make shaft less run out, make bearing work in good steady and make rotor stator to reach good emulsification effect.

Why Do You Need an Inline Homogenization Pump?

One important question need to clarify before answering this question is that what is homogenization and what is homogenization used for?

Homogenization is a process of reducing various substances to extremely small particles and distributing them uniformly in a fluid to get a stable consistent mixture, ranging from watery liquid to thick creams.

Under what circumstances should we need inline homogenization pump?

If you want to make material particle size smaller, to make powder distrubuted evenly into a liquid to get stable homogenization slurry;

If you need pre-mixing or recycle emulsificaiton in a continous production line.

Hot Tags: ELR Series Homogenizer Pump, suppliers, manufacturers, cost, price, for sale