Bead Mill For Nano Fertilizer

ELE Bead mill is suitable for Nano Fertilizer. Guarantee the diameter of the micelles of the cementing and coating agent of nano-fertilizers are all within 100 nanometers. The small size effect of nano-materials can make the fertilizer particles have a magnetic effect, so that fertilizer nutrients can be more easily absorbed by plants and effectively stimulate plant growth.

ELE Bead Mill ENW series and EDW series are Nano bead mill, that could effectively help to reach the 100nanometer particle size. And get Narrow particle size distribution.

Sand Mill for Nano Fertilizer

Media Mill for Nano Fertilizer

1)Multiple cooling system

ELE Bead Mill with multiple cooling system, that provide sufficient cooling performance, better in heat dissipation,

1: Grinding Chamber with jacket for cooling

2: End cover with jacket for cooling

3: Feeding Pipe with jacket for cooling

4: Independent cooling tank for mechanical seal

2)Concentrated energy and higher kinetic energy

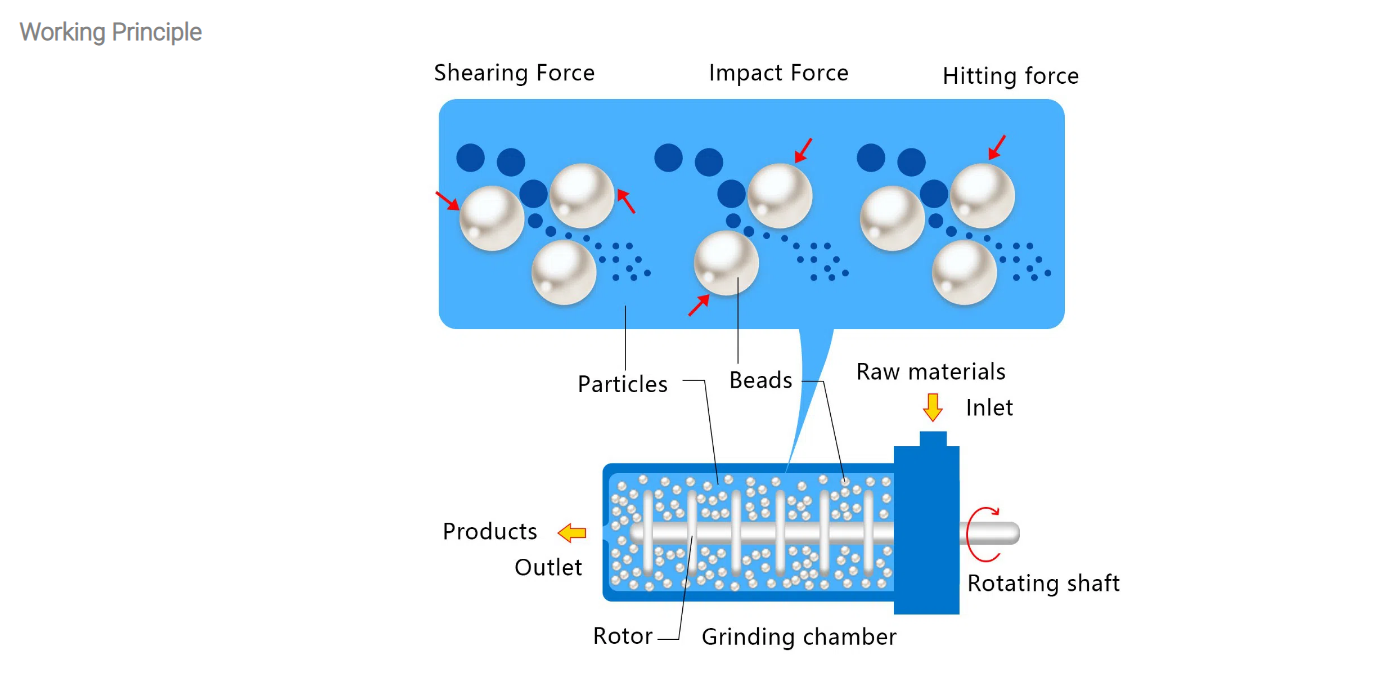

ELE Bead Mill with short and fat design of grinding chamber, that could create concentrated energy and higher linear velocity, bring higher kinetic energy, that bring impact force, shearing force and hitting force, easy to bring ultra-fine particle size.

Three Types of Contact material for option

Harden Alloy Steel:

Strong Wear resistance, Alloy with special treatment, Hardness reach HRC62

Ceramic:

With Special ceramic material: zirconium or silicon carbide, Stronger wear resistance, No Metal contamination, Hardness reach HRC72-78.

PU polyurethane :

No Metal contamination

Application

Bead Mill used for Nano Fertilizer Zinc Oxide, reach 92nanometers

Hot Tags: bead mill for nano fertilizer, suppliers, manufacturers, cost, price, for sale

Bead Mill

● Getting higher efficiency production capability: Stable continuous working, smoothly discharge, smoothly production, high energy, short the grinding time.

● Getting higher quality products: Narrow particle size distribution and finner particle size makes higher quality products

● Good after-sales-service let you no worries

● Low maintenance cost

ELE Bead Mill Machine cooperates with Switzerland technology, with advanced structure, high efficiency, nanometer, and micron final fineness. It adopts specially wear-resisting materials, prolonging service life, and well adapted to different viscosity of materials.

It is widely used in the industrial production of paint, color paste, printing ink, papermaking, adhesive, drugs, chemical industry, etc.

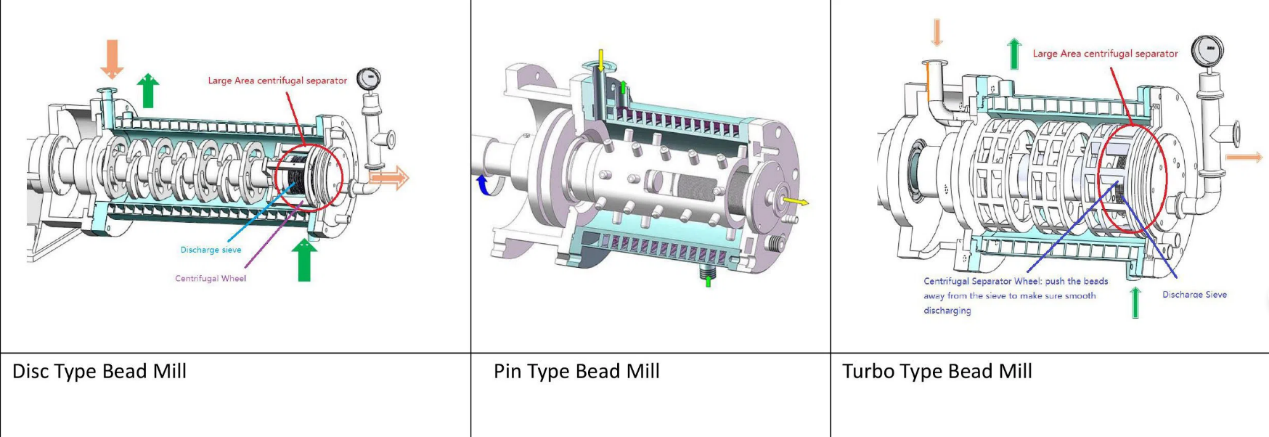

Pin type and Turbo type are nano grinding mill, with the special short and fat grinding chamber, energy is concentrated, with higher tip speed and higher impact force and friction force. Disc type is cost-effective sand mill, suitable for that product which don’t required too much on particle size.

ELE: Your Leading Bead Mill Machine Manufacturers in China

● Over 20 Years Manufacturing Experience

Shanghai ELE established since 1996, built China mainland factory at 2006, with R & D, Manufacturing, Global sales & Marketing together.

As a leading bead mill manufacturer with 20 years ,This Bead Mill manufactured by ELE team is your reliable Wet Grinding partner, which can grind products into small particle size, like micron size, nanometer size, it will solve all the ticklish problems in processing, like material fineness, temperature, output, pure color and metal contaminations.

ELE bead mill provide three kinds of material for options, suitable for different application area:

1).Harden Alloy Steel rotor and inner grinding chamber,

2).Ceramic Material: Zirconia Rotor and Silicon carbide inner grinding chamber,No metal contamination, better in heat conductivity, suitable for electrical material, medicine , food that requires free-metal.

3).PU material: polyurethane Rotors and inner grinding chamber No metal contamination

ELE Bead mill machine Widely used in:Paint、Ink、Pigment、Pesticide、Biological、Medicine、Golves 、Electronic Materials、Nano Materials,and many other applications

The capacity of the bead mill ranges from 5L to 100L and can grind to nanometer 50nm~500nm ,micron-size 1 micron~ 10 microns...

● Reputation certification

As a leading bead mill manufacturer with 20 years of experience, all bead mills manufactured by ELE® undergo 100% testing before delivery to ensure that the products meet the delivery conditions.

ELE Bead mill machine have CE, SGS, TUV certificate.

ELE is the only manufacturer who has its own mechanical seal patent in Shanghai. Patent No.: 201610459850.7

● Quality Control

With around 25 years rich experienced engineers in this area, ELE strictly control the every single process from raw material to processing, to assembling to final products testing. Strictly control the accuracy during processing,

For equipment, superior performance sometimes does not mean good quality. Quality can be understood as mechanical stability which means it will not be damaged or malfunction frequently. Therefore, the definition of an excellent equipment should has excellent mechanical stability on the basis of superior performance.However,how to ensure the quality of the equipment? We think It needs to start from two aspects:

1. High requirements for accuracy;

2. Strict quality control management system

First of all, accuracy is extremely important to the equipment. For example, if the accuracy of the sand mill is not good, the main shaft will happen runout greatly, which will damage the mechanical seal in a short time and seriously affect the service life of the mechanical seal.

However, accuracy is actually a display of the comprehensive technical level and manufacturing capabilities of the machinery manufacturer due to it involves many aspects of manufacturing. For example, excellent design(structure), complete and high-quality process equipment (machine tools), reasonable and excellent processing technology, skilled technical workers, strict inspection system,and so on. The figure below is a simple diagram.

For quality control, ELE has strict requirements at every step. We have a professional inspection department which is responsible for each step of the inspection, and we also have a strict inspection system which involves in inspection of raw materials, single processed parts, assembly parts, dynamic and static inspection of machine.,and so on.

In summary, Excellent design&accuracy&quality control management system are a solid guarantee for the quality of ELE equipment.

Bead Mill Machine: The Ultimate FAQ Guide

What is Bead Mill Machine?

Bead mill machine is also called pearl mill or sand mill. These names strongly indicate that this mill is working on beads or pearls…It is mainly used for wet grinding of all kinds of the chemical liquids, such as paint, coating, ink, pigment, pesticide…any chemical liquids which pursue smaller particle size, like micro or even nano-meter…According to the performance, Agitator Bead mill can be roughly divided into horizontal bead mill(simply we call it bead mill), basket mill, vertical ball mill . The machine is mainly composed by the body shell, the grinding cylinder, the grinding disc, the grinding medium, the motor and the feeding pump. The feeding speed is controlled by the feeding pump. The grinding media of the device are generally classified into zirconia beads, glass beads, zirconium silicate beads, steel balls. Technically, smaller beads can achieve smaller particle size..

Bead Mill is a wet grinding mill, which can grind products into small particle size, like micron size, nanometer size, it will solve all the ticklish problems in processing, like material fineness, temperature, output, pure color and metal contaminations.

Bead Mill is the high efficiency, high energy wet grinding mill, with the multiple cooling system, automatically stop control system, with continuous production system.

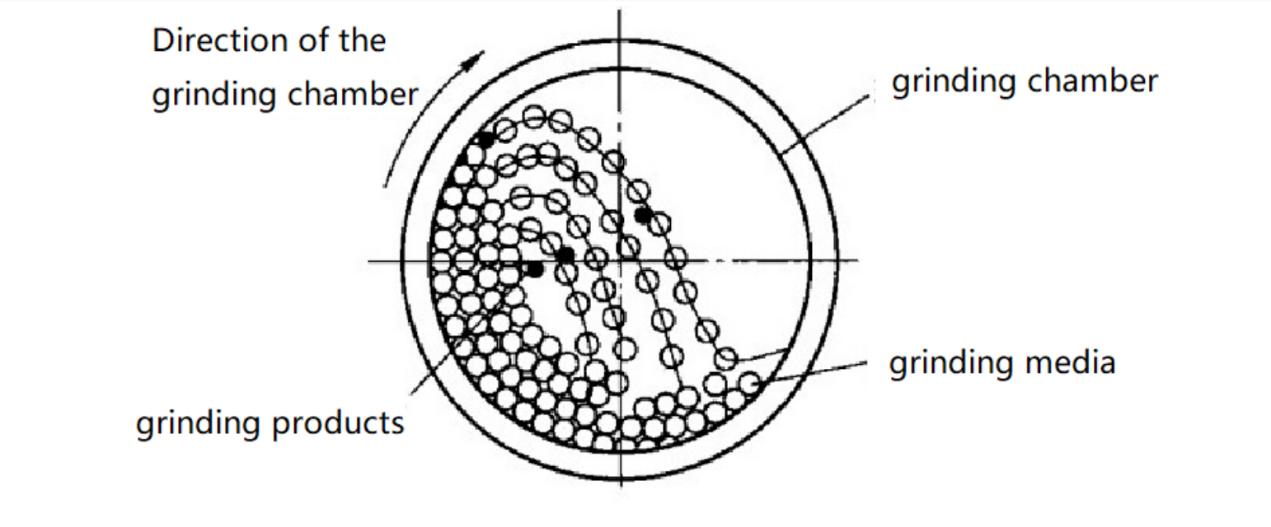

The bead mill is the most widely used, most advanced and most efficient grinding equipment so far. The grinding chamber is the narrowest, the gap between the grinding disc is the smallest, the grinding energy is the most dense, and with the high-performance cooling system and automatic control system, bead mill can realize continuous working, which greatly improves the production efficiency.

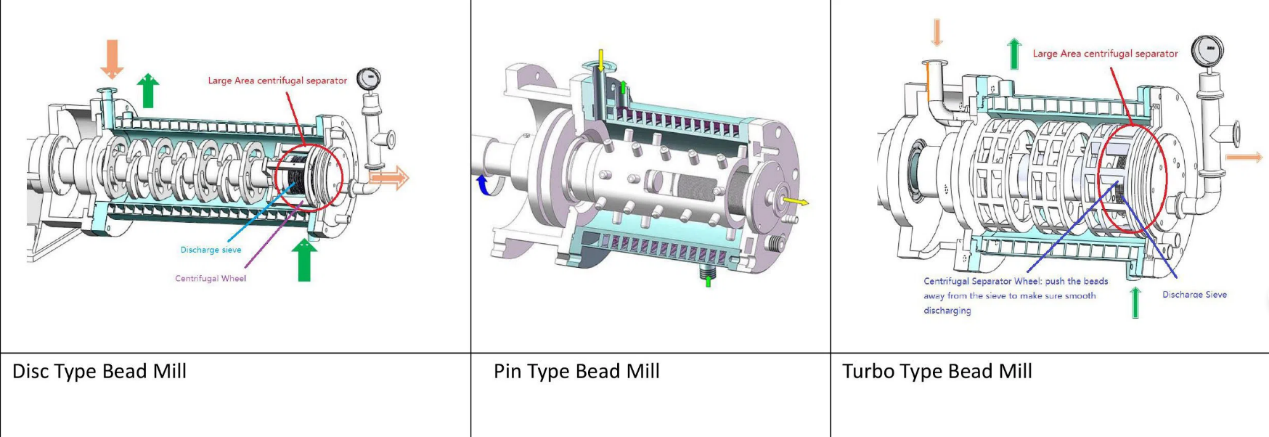

Horizontal bead mill is developed based on ball mill. According to different structure(mostly the different grinding disc)And it can be classified as disc type horizontal bead mill, pin type horizontal bead mill, turbo type horizontal Agitator Bead mill…Different type has different performance and you can choose the right machine according to your product and your working capacity.

What Are the Advantages of Bead Mill Machine?

The advantages of bead mill very obviously compare with other grinding mills ( basket mill, three roller mill )

From bead mill and basket mill and three roller mill working principle

You can see bead mill's most obvious advantage is suitable slurry mass continuous production and high production efficiency.

Bead mill machine can grind to nano-size 50nm,100nm,200nm,500nm...

Bead mill machine also can grinding to popular micron size 1 micron, 2 microns 5 microns,10 microns...

High performance and high energy

Grinding media is evenly distributed inside the grinding chamber, the final particle size is narrowly distributed.

ELE-NET0.1 discharging sieve is designed for superfine material, to ensure of large flow rate, and microbeads can be used at the same time;

Selection of special material (zirconia/silicon carbide/hard alloy steel etc.) enhance the wearability of all processing contact parts, It adopts an internal thread type cooling way, effectively improves heat dissipation in the grinding chamber.

Unique double cartridge mechanical seal, to ensure long operation of the shaft seal, maximum 8 -10 kg pressure

Special Feeding System

Feeding pump with buffer tank to make sure feeding smoothly, buffer tank with pressure meter, If the grinding chamber is blocked, we can release the pressure from the buffer tank

Discharging System: New technology of Discharge method

Large Area centrifugal separator, the centrifugal wheel push away the grinding beads from the discharge sieve, make sure discharge smoothly, no blocking of beads

Special Mechanical Seal & Bearing Housing

● Special double cartridge mechanical seal, ensure long operation of the shaft seal, maximum 8 -10 kg pressure;

● Special Bearing Housing, match mechanical seal well, one whole part, ensure the accuracy to below 0.03mm. Make sure stable working & extend the long life.

Cooling system

● High-efficiency large area spiral ribbon type jacket water circulation chamber wall cooling

● Feeding pipe with the jacket for cooling

● End cover corrugated cooling

● Cooling Tank for Mechanical Seal

Are There Limitations of Bead Mill Machine?

we have lab bead mill and large production bead mill , Most materials can use our bead mill grinding, Except for materials with high viscosity or poor fluidity can not use Agitator Bead mill, But from our experience, high viscosity materials not require high fineness.

What is Bead Mill Machine Used For?

Bead mill machine use for slurry grinding ,widely use these industry

● Paint: Decorative paint ,Car paint, Wood paint, Floor paint metal paint etc;

● Ink: Gravure Printing ink, Flexographic ink, Offset printing ink, Silk screen ink, UV light solid ink, Digital inkjet ink etc;

● Pigment: Pigment ,Dye, Color painted pigment, Pen liquid,Watercolor;

● Pesticide: Pesticide suspension, SC,EC, EW, ME;

● Biological Medicine: Algae cell fragmentation, Micro-biological functional materials;

● Golves : Labor,latex ,nitrile gloves

● Electronic Materials: Battery diaphragm alumina, Lithium iron phosphate, Ceramic slurry, Flame retardant;

● Nano Materials: metal oxide, Magnetic Materials, Paper industry, Optoelectronic industry.

Which Other Technologies Can Replace Bead Mill Machine?

Basket mill can be a replacable mill machine of bead mill. It can achieve utlra-fine grinding effect too. Comparatively speaking, the two types machine have its own advantages.

For bead mill, motor power is larger, beads filling ratio is higher, grinding time is shorter and target particle size distribution is narrower. And it can be used to continuous production in that the bead mill is highly automated. Not only because protective devices can be installed on the bead mill and it can automatically shutdown if machine pressure beyond set value, so that one person can operate multiple machines, but also because the machine cleaning and grinding process are the same , thus don't require workman to do cleaning else. But the price is higher.

For basket mill, it can do grinding and dispersing together, convenient to operate and easy to clean so it particularlly suitable for paint and ink production with many colors. But it requires workman to transfer materials and clean inner basket chamber after grinding every time. And also it can't be used in continous production. But price is lower.

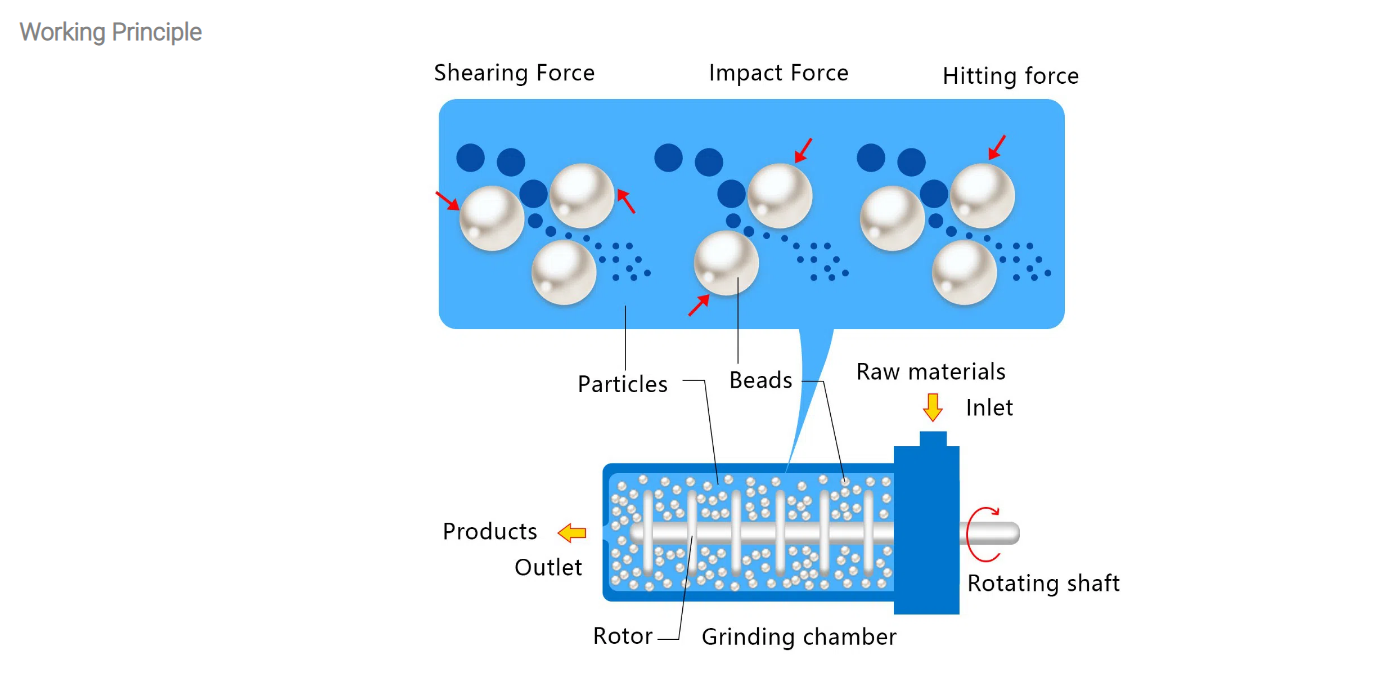

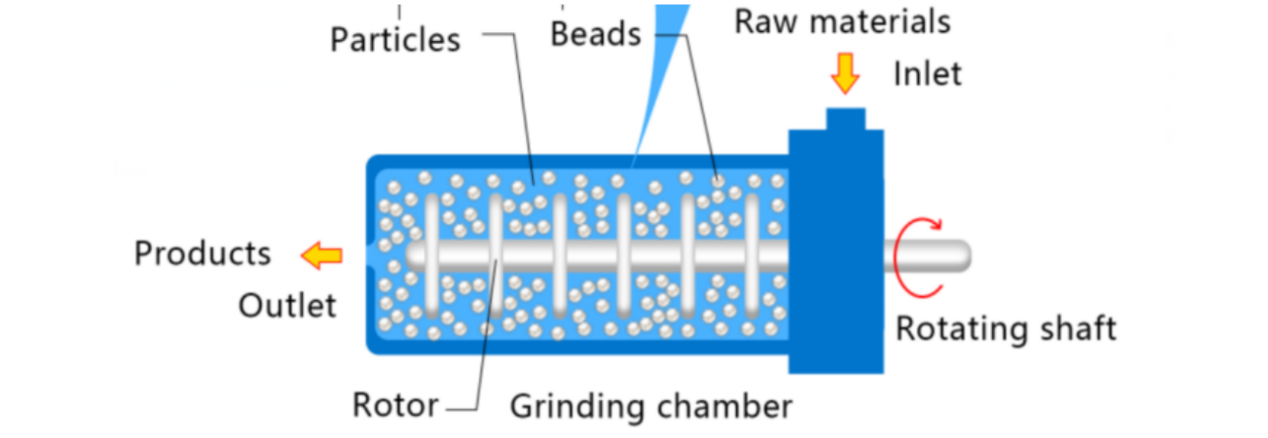

How Does Bead Mill Machine Work?

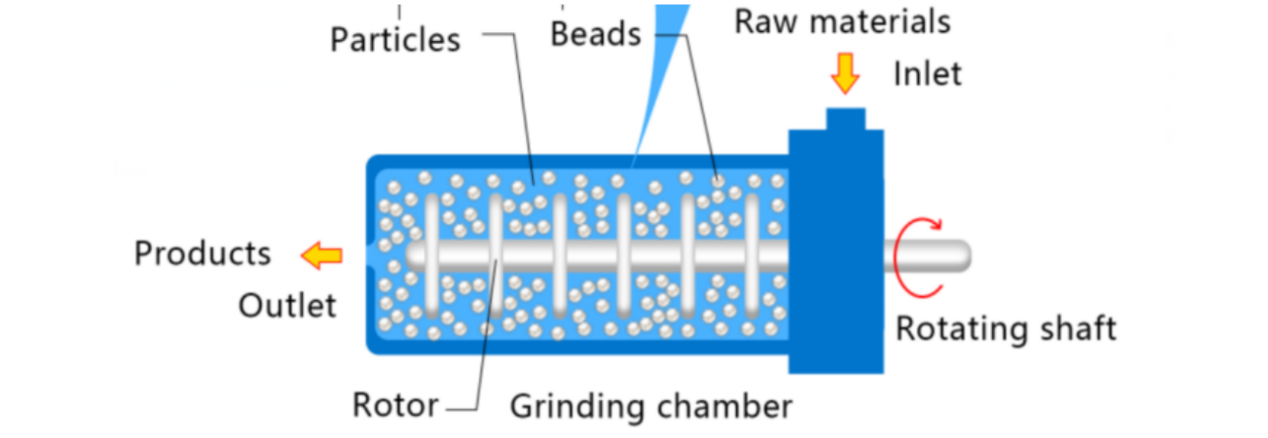

Motor of bead mill machine drive in high speed, bring the rotors (Pin/Turbo/Disc) in high speed rotation, the beads between the rotors are moved fast and collide each other, bring shearing force, impact force and hitting force to the particles, break the particle to be smaller size. With the help large area centrifugal separator sieve, the grinding media keep stay inside the grinding chamber, the particles go through the sieve gap (usually 0.1mm, 0.3mm, 0.5mm, we also can make 0.05mm) for discharge.

A horizontal bead mill is wet grinding machine for continuous production. The working way is:

Working Principle

Bead Mill Machine Working Principle

Feeding pump: like diaphragm pump or gear pump, to transferring the material into the grinding chamber which is filled with grinding media (normally it is Zirconia Beads, glass beads or steel beads. We recommend you 95% zirconia content Zirconia beads).

Grinding: These beads move along with high-speed Grinding disc. The grinding beads hit against the material which needs to be grinded with high power.

Discharge: After thousands of times hitting, the material will get smaller particle size, and then it will be separated with the beads by a special sieve which installed in the middle of the grinding chamber cover.

Compared to three-roller mill, bead mill doesn’t need high working skill, easy to operate, and bead mill can work continuously on production line, by this way, using bead mill, you will get high quality product, and lower cost.

On the market, there are several types bead mill such as: disc type bead mill, pin type bead mill, turbo type bead mill, and each type have different size, to satisfy different customer’s need: different product, different viscosity, different working capacity….

In all, bead mill is now widely used in Industry such as: paint, ink, medicine, food, cosmetics, pesticide…

How Many Types of Bead Mill Machine Are There?

In terms of machine rotor structure, we have three types: disc type, rod pin and turbine. In terms of rotor and cavity materials, we have alloy steel, ceramics, and polyurethane.

How Do You Troubleshoot Bead Mill Machine?

Generally, our equipment will be shut down when a failure occurs. Do not rush to restart the machine at this time. Turn on the electric control cabinet first and the fault indicator will light up. Through the fault light, we will find out the corresponding fault location and cause.

Faults and Troubleshooting Method:

A)Feeding pump can not transfer materials or showing pressure>2kg on the pressure meter

I. Check feeding pump

II. Check whether chamber discharging end blocking, open the outlet port nozzle, clean the discharging sieve.

B) Main motor doesn’t work

III. Check power supply

IV. Security instrument is in protection state, floating ball of liquid level falls to the bottom of the central pole or pressure in mechanical seal cooling tank is too low, ﹤0.25Mpa.

V. Check thermal relay

VI. Check whether cooling liquid transfer pump is working normal

C) Rotor don’t rotate ( while main motor is working)

VII. V-belt is too tight

VIII. Rotor is stuck by media or materials

After troubleshooting, press the emergency stop button. Restart the machine

What Are the Factors That Affect the Service Life of the Bead Mill Machine?

Failure to operate the machine in accordance with our training guidelines.

1. The feed particles are too large or the viscosity is too high to cause the machine block, and the machine is forcibly restarted when the fault is not eliminated. It is very likely that the mechanical seal will be damaged after several times, resulting in liquid leakage.

2. When the current and voltage are unstable, it will cause damage to the motor and abnormal shutdown.

3. The cleaning of the material is not complete, and the material remains in the cavity, which causes the filter screen to be blocked.

4. The mismatch of the selected zirconia beads and the filter screen, and the feeding speed is too fast, will cause the machine to block and cause the shutdown phenomenon.

The above behaviors will affect the service life of the machine.

Which Factors Control Particle Sizes in Bead Mill Machine?

There are many factors that may influenced the final particle size, such as:

1. Grinding type, there are three types bead mills in term of grinding types, Disc type, Pin Type, Turbo type, each type due the grinding efficiency and energy consuming different, the final particle sizes will be different too.

2. Zirconia beads size, when bead mill working , shaft bring engergy to zirconia beads which cause crushing power on the particle size, the gap space among beads and beads influence the smallest particle size it can reach.

3.Beads loading ratio, in a reasonable scale, the higher beads loading ratio, the higher grinding efficiency, more beads means more crushing power and possibility that hits the particle size.

4.Speed, the higher rotating speed brings higher power and energy, in reasonable scale, the speed is higher means efficiency is higher too.

5.Feeding speed, feeding speed lower means that material has longer grinding time in the grinding chamber, this influence the final particle size too.

6.Temperature, pressure, etc, according to different material characteristics, sometimes temperature and pressure will influence the final particle size too.

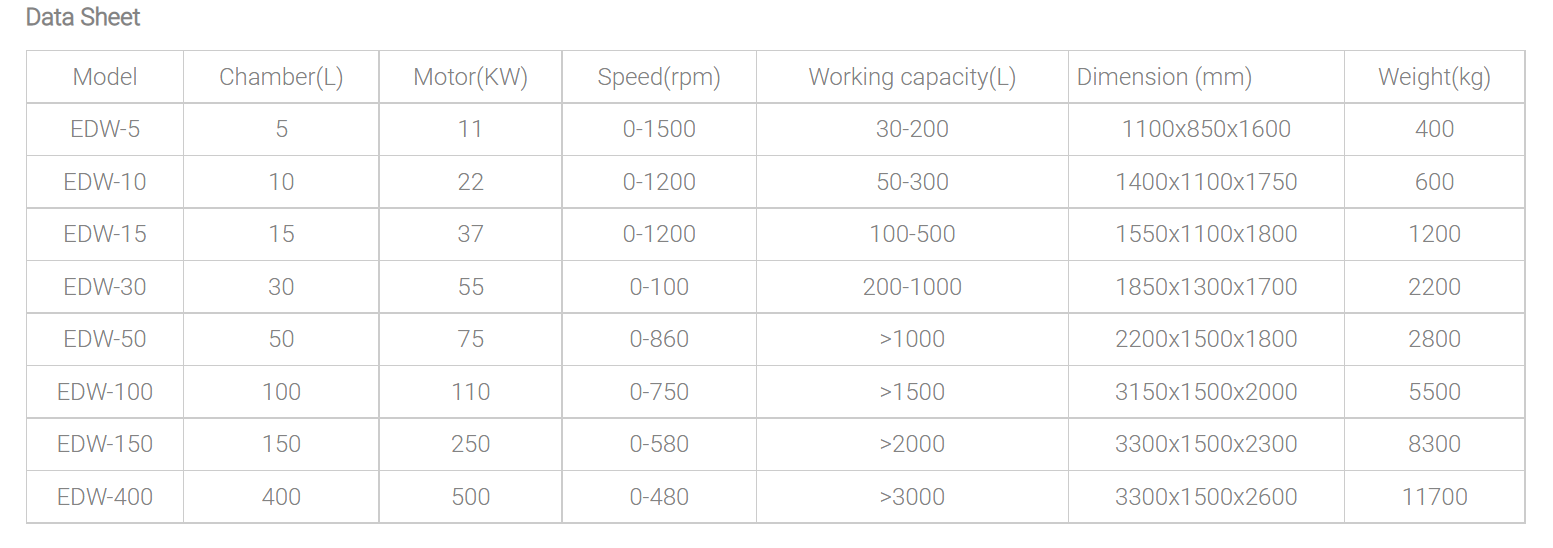

What Are Bead Mill Machine Specifications?

When we say the specifications of a bead mill, we generally starts from the following aspects:

1.the grinding type, such disc type, pin type and turbo type.

2.the grinding part material, metallic and ceramic.

3.the motor power.

4.the grinding chamber volume

5.the sieve size

6.the zirconia beads size

7.the other assisting devices

What Are the Properties of Materials You Can Process Using Bead Mill Machine?

Horizontal sand mill is a wet fine grinding equipment. Its main function is to break the phenomenon of secondary agglomeration of particles. At the same time, it has a certain crushing ability according to different physical properties. Therefore, the products produced by sand mill must have at least the following two characteristics:

1. The working manner of sand mill is wet grinding, so the material is required to have fluidity and be in the state of slurry, liquid, solid-liquid mixture, etc. The products produced by the sand mill are finally in the state of fluid slurry, suspension agent, etc., not powder state.

2. Sand mill is aimed at fine grinding, so it has requirement for the feeding particle size (preferably less than 100 microns). The material needs to be fully pre-dispersed before entering the sand mill.

How to choose a suitable bead mill?

What kind of products you will grind? Water-based or solvent-based

What is the viscosity? How many cps ?

What is the final particle size you want to reach? How many microns?

What is the initial particle size? How many microns?

What is your working capacity? How many liters per batch or per hour?

Please contact our sales and inform him/her of product information

How To Choose The Suitable Bead Mill According To The Capacity Requirements?

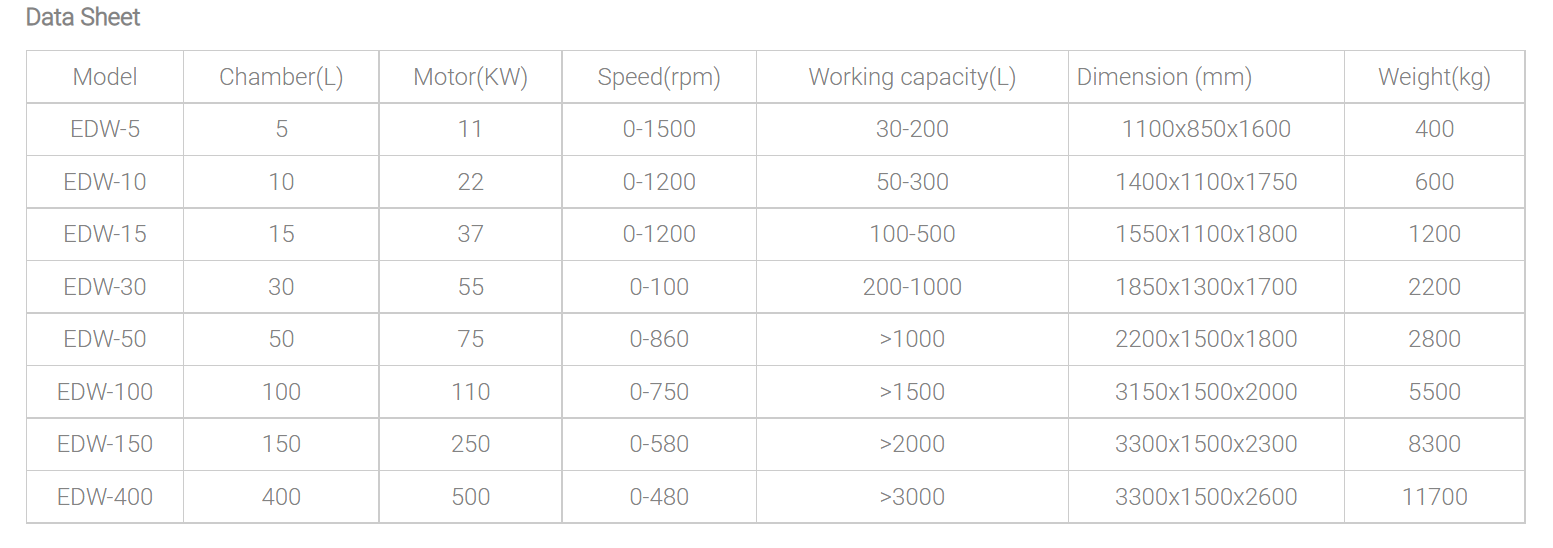

Commonly used production bead mills are 5L, 10L, 15L, 30L, 50L, 100L, etc.

This refers to the volume of the grinding chamber of the bead mill, However, many user no idea about what is the relationship between this grinding volume and the production capacity of bead mill

In fact, the volume liter of the grinding cavity only determines the amount of material passing through the grinding cavity per hour, that is what we usually call the flow rate, But the flow rate is not equal to the capacity at most time, Most materials, especially that require very fine fineness,

such as nano size, this kind of fineness requirements cannot be achieved once in the grinding machine. Then choose bead mill must consider characteristics of the material and the fineness requirements . For example, the flow ability of the material, the viscosity, the original particle size of the raw material distance of the target fineness, all need to be considered.

Exactly, the specific capacity requirements and the selection of bead mill volume are more based on experience data , or actually calculated by the grinding data of the material, generally based on the number of grinding times to achieve the target fineness as a parameter, some materials need coarse grinding one times , this materials flow rate is equal to capacity ,

for most materials, need grinding 2 or 3 times ,plus the theoretical flow of bead mill ,Then can be choose bead mill .And different material will have differences in real working capacity

Therefore, as professional bead mill manufacturers, the large amounts of data accumulated in various industries are very important to users. So communication with the professional sales engineers of the bead mill manufacturer are particularly important when selecting bead mil. Sales engineer can quickly and efficiently help you to successfully select suitable bead mill to avoid large discrepancies in output.

How To Choose The Bead Mill For Different Fineness Requirements?

At present, Our company main bead mill types include disc bead mill, pin bead mill, and turbo bead mill.

Normally , the disc bead mill grinding fineness worse than pin type and turbo bead mill. The disc bead mill more used when the fineness requirements are not high, example 10 microns fineness or the micron grade fineness is required..

The pin bead mill is more used for materials with sub-micron and nano-grade requirements less than 5um. However, due to the special structural advantages of the pin bead mill, it is also widely used in the case of high material viscosity. Of course, in other situations, such as improving efficiency, you can also choose a pin bead mill as the object of choice. In short,except for special circumstances, generally the pin type bead mill can do disc bead mill work

With the continuous development of Bead mills, and to meet higher requirements for fineness, efficiency, and fineness distribution of materials, the emergence of ELE turbo-type bead mills is that the various indicators of the current three bead mills are more outstanding. More balanced. In other words, if you not only have finer requirements for fineness, but also want narrower distribution, then you can consider a turbo bead mill

Why ELE bead mill equipped zirconia, silicon carbide, polyurethane, high wear-resistant alloy steel for options?

When customer choosing the bead mill, Customer will feel that there are too many material configurations of the bead mill. Them don’t know choose which one ? In fact, ELE bead mills are made of zirconia, silicon carbide, polyurethane, high wear-resistant alloy steel and other different options. Customer should choose bead mill according to working purpose

The right bead mill meets your required is the best. It is recommended that you communicate with ELE sales engineers in depth, as their experience in various industries will definitely give you something to gain.

bead mill

When customer choosing the material of the bead mill, the main considerations are wear-resistant life, metal pollution, temperature control, applicability to the material, and price. No matter what kind of material will wear during grinding under certain working conditions, there is a difference in the amount of wear per unit time. Don't listen to the fallacy that won't wear out.

First of all, let’s introduce the characteristics of each material. Zirconia is wear-resistant but not easy to dissipate heat. Silicon carbide is wear-resistant and easy to dissipate, but the processing technology has limitations. It is mostly used for grinding shell. Polyurethane is the best wear-resistant material in organics and its chemical stability is also Very good, but not as wear-resistant as inorganic materials such as zirconia silicon carbide, and is most suitable for working conditions where inorganic materials cannot be present. Finally, the most commonly used high wear-resistant alloy steel material has good wear resistance and is low in price compared to the above materials. It is the preferred material when there is no special requirement.

In addition, the quality of the materials is also different. Many suppliers of poor bead mills use zirconia and silicon carbide ceramic manufacturers in small workshops to reduce costs, and their quality cannot meet the high wear resistance requirements of bead mills. This is also one of the important reasons why many users choose the good reputation brand of ELE when choosing bead mills, and users who have used ELE bead mills basically will not choose other brands.

How To Adjust The Grinding Fineness Of ELE Bead Mill?

If the grinding fineness of the bead mill can be adjusted? Yes ,it can be adjusted.

But it can only be adjusted within a certain range. Why will say that?

Because it depends on the physical properties of the material. The limit fineness that each material formula system can reach is certain. When this limit fineness is reached, it will not be infinitely finer due to the adjustment of the parameters of the bead mill.

Therefore, adjusting the grinding fineness of the bead mill can only aim at this limit fineness, and reach or approach this limit fineness in the shortest possible time. This is the meaning of adjustment. Of course, the first thing is to choose the suitable bead mill, otherwise it will be useless to adjust. Then adjust the operating parameters of the bead mill, such as flow, speed, temperature, pressure, bead size, loading ratio, etc. But if no one knows what the ultimate fineness of this material is? Then what should we do?

In fact, it is possible to know whether it is close to the limit value of the fineness of ELE bead mill. When use ELE bead mill, and continuously adjust the operating parameters and grind multiple times, every time it is tested with a laser particle size analyzer, the test results will always have a downward trend. But when the trend of fineness decline is not obvious or there is basically no further decrease, we can consider that it basically reaches or approaches its limit fineness. it basically happens every day in ELE ’s laboratory. Based on this kind of experiment, Many users also commented: When ELE bead mill can no longer grind, other sand mills basically do not need to be tested.

Want to know how to adjust the grinding fineness of the bead mill? Only by choosing the right bead mill and then truly understanding the operation mechanism of the sand mill can you do it.

What Should Be Paid Attention To When Choosing A Bead Mill For Solvent-based Paints And Inks? Explosion-proof And Mechanical Seal Especially Important!

When it comes to solvent-based paints and inks, explosion-proof are often considered when considering equipment selection. When asking ELE professional engineers, they will actively ask whether the material is solvent based or water-based.

The explosion-proof of the bead mill is mainly the electrical part, and the mechanical part itself does not explosion. The explosion-proof bead mill mainly includes explosion-proof motors, explosion-proof control boxes, explosion-proof instruments and meters, and explosion-proof wiring. However, the power distribution cabinet is rarely explosion-proof. On the one hand, it is expensive to make the power distribution cabinet explosion-proof. On the other hand, it is really unnecessary. The power distribution cabinet can be placed in the power distribution room instead of the operation site.

The explosion-proof requirement level also needs to consider the design requirements of the plant and the local fire protection. This is very important, not only for the needs of fire inspection, but also for safety considerations. When choosing a bead mill, you must choose a brand manufacturer. This is also one of the important reasons why many customers choose ELE

sand mills. The old brand technology is reliable, durable, and safe.

In addition to the determination of explosion-proof requirements, another important issue is sealing. There are many kinds of solvents and strong polarity. The requirements for sealing are completely different water-based materials. As far as the static seal is concerned, it is mainly the choice of the material of the O-ring. In this regard, we must communicate the name of the solvent with the sales engineering of ELE to determine the material of the O-ring.

Another more important component, the dynamic seal is also the mechanical seal, and the solvent should also be considered. It is very necessary for these to communicate clearly with ELE sales engineering.

How Long Does It Take To Replace The Filter Screen Of The ELE Bead Mill?

The filter screen of the bead mill is a very important part. Its function is to keep the grinding beads in the grinding cavity, and the material discharge smooth. As material fineness requirements become finer, the grinding beads used are getting smaller and smaller. This requires higher and higher precision of filter screen area

However , the filter screen is installed in the grinding chamber , and it is in constant contact with the grinding beads, so normal wear exist. The filter screen of the ELE Bead mill has a unique design, which can minimize the contact and friction of the grinding beads on the filter screen during grinding. There are two aspects. One is the reasonable control of the distance between the center installation and the rotor. On the other hand, the spin-wheel structure of the rotor can quickly separate the grinding beads. Another important factor is the processing design strength of the filter screen itself and the wear resistance of the material. This is also an important reason why the filter screen of the bead mill has been evaluated as good in the industry for so many years.

Under normal circumstances, excluding the factors of material hardness and wear, the use time of the filter is more than 1-2 years. This is the case of 80% bead loading ratio of ELE bead mill. Theoretically, the lower the bead loading ratio, the less wear of the filter screen and the longer the service life.

What Is The Amount Of Zirconium Beads Added To The Bead Mill Machine?

Whether the amount of zirconium beads added in the bead mill is appropriate will directly affect the working efficiency and fineness of the bead mill during grinding. Too little will reduce the efficiency and fineness, and too much will cause problems such as excessive heat generation.

To understand the amount of zirconium beads added to the bead mill, you must first understand the loading ratio.

Because of the differences in the technology of each bead mill manufacturer on the market, the required grinding beads loading ratio is also different. Generally, most bead mill manufacture loading ratio is 60-70%, But ELE bead mill grinding beads loading ratio of can be 60- 80%. In theory, the higher the loading ratio, the better the grinding fineness efficiency, so the loading ratio is also an important indicator to measure the quality of a bead mill.

What is the loading ratio? The loading ratio refers to the ratio of the loaded beads to the effective volume in the grinding chamber. So how much loading ratio is appropriate? This is related to the model, grinding fineness, material viscosity and temperature requirements ... we suggest that you consult ELE sales engineers to determine the appropriate loading ratio.

However, the calculation of the loading ratio is the volume rather than the weight. Therefore, in addition to understanding the loading ratio, you must also understand the specific gravity of the zirconium beads. The specific gravity here does not refer to the true specific gravity, it is a bulk weight or bulk density. Now the question is, what is the bulk density of zirconium beads?

It depends on which zirconium beads you choose? There are many varieties of zirconium beads on the market, and the quality varies greatly. The common is zirconium silicate beads and pure zirconia beads. ELE bead mill not allowed to add zirconium silicate beads to mill. We recommended to add pure zirconia beads with a zirconium content of more than 95%, with a bulk density of 3.65 -About 3.7g/cm3.

How to measure whether the zirconium beads you choose are pure zirconium oxide beads, Here is a simple test method. After peeling the measuring cup and weighing, take out 100ml of zirconium beads. The specific gravity is about 3.6 when the weighing reaches 360g (human error may exist, it is recommended to measure 3 times). If it is less than 360g, the zirconium beads may not be true pure zirconia beads.

After understanding the loading ratio and the specific gravity of zirconium beads, the amount of zirconium beads added to the bead mill can be calculated according to the following formula:

Theoretical addition amount = effective volume of grinding cavity * filling ratio * specific gravity of zirconium beads

In actual application, you can make certain adjustments based on this theoretical addition amount, and ELE engineers will also set up the best operating parameters for you during on-site debugging.

Special statement: The content described in this article is only for reference by users who have purchased ELE equipment, and may not be used or reproduced without permission.

Is It Easy To Clean The Bead Mill After Grinding The Color Paste

The cleaning problem of the bead mill after grinding the color paste is the most troublesome thing for all people who have used grinding mill. The workload is too large, and it takes time and solvent, which is very troublesome. If compare which bead mill is the most convenient for cleaning. The most powerful answer to this question is bead mill operators of color paste

After a lot of survey it was found that most operators said that the cleaning of the bead mill is mainly divided into two parts: one is disassembly and the other is cleaning. In fact, it is not too difficult to clean. Every bead mill is basically the same. As long as it is turned on circulation cleaning or replaced by a set of grinding beads, it is fairly convenient. The most difficult thing is actually disassembly and assembly. Many bead mills spend 80% of the entire cleaning work in disassembly and assembly, resulting in low production efficiency.

The unique design of ELE Bead mill is indeed very user-friendly, especially the design of the upper pull plate of the grinding cavity and the 180-degree rotation without dead angle. This unique humanized design of ELE company makes disassembly and assembly extremely simple. The old-fashioned traditional bead mills are basically designed with double pull rods. The grinding shell is cumbersome to pull and cannot rotate. There is a dead angle in the cleaning of the rotor gear, which makes the cleaning efficiency extremely low.

Another easy disassembly and assembly of ELE bead mill is that all pipelines adopt clamp-type quick connection, which can be disassembled and assembled manually without special tools, which greatly shortens the time of disassembly and assembly.

Operators who have used the ELE Bead mill feedback, convenient, quick and easy to use. Not only the grinding efficiency is high, but the cleaning efficiency is also efficient. Improving efficiency is to improve economy,This is one of the reasons why it is liked by users.

Is there much residual material in the grinding chamber of the wet grinding mill machine?

The residual amount of materials has always been a general concern of users, and the amount of residual amount is also an important indicator to measure the rationality and cost-effectiveness of a piece of equipment.

However, ELE Bead mills have fully considered this detail at the beginning of the design. First, when designing the pipeline, minimize the length of the pipeline and increase the number of quick connections. The design of the grinding cavity also follows the golden section aspect ratio design, which not only ensures the maximum grinding efficiency, but also minimizes the ineffective grinding area of the material, which is to reduce the residual material.

In addition, there is another important factor, which is the loading ratio of the grinding beads. Compared with the traditional bead mill, the loading ratio of grinding beads is higher. In other words, the remaining material space is less, so that the residual amount of the material is reduced to the greatest extent.

In fact, compared with other bead mills in the industry, the residual amount of material of the ELE bead mill has a relatively large advantage, accounting for about 12-16% of the volume of the grinding chamber.

In practical applications, bead mills are usually widely used in mass, continuous production. Therefore, there will be no regular cleaning, which will cause a lot of waste of residual materials. If there are special circumstances, such as small-batch multi-variety production, the need to replace the product, the frequency of cleaning is high, or the product value is high, and waste is not allowed, then we recommends you to consider ELE development for this situation Another high-efficiency grinding equipment---basket bead mill

What are the wearing parts of the horizontal bead mill machine?

After normal use, the horizontal bead mill will produce damaged parts like all machinery, These normal damaged parts are called wear parts. The occurrence of these conditions has been taken into account in the design of the horizontal bead mill, so the design of ELE engineers is also based on the principle of reducing maintenance or replacement costs. So, what are the wearing parts of the horizontal bead mill? There are three main wearing parts: one is seals, the other is wear parts, and the third is fatigue parts.

Let me talk about sealing first. Seals are divided into static seals and dynamic seals. The static seals are mainly O-rings. It depends on the type of material solvent, the frequency of disassembly and assembly, and the use time. Generally, it is recommended to be between six months and one year. Check or replace once. The dynamic seal is the mechanical seal that is often referred to. It can basically be used for more than three years or longer under normal working conditions, but it needs frequent maintenance, such as replacing the coolant. For details, please refer to the instruction manual.

The other type is wear parts, mainly the rotor in the grinding cavity, especially the rod pins. Due to the hardness of the grinding medium and the material particles, the wear condition will be different. This needs to be opened regularly for inspection. There is also the discharge filter. It is recommended to replace it regularly for about 10-15 months depending on the grinding frequency. Do not wait for the beads to leak before replacing it, otherwise it will be more troublesome to wait for the beads to leak into the material before processing.

Finally, there are fatigue parts, one is the belt of the transmission, and the other is the diaphragm of the diaphragm pump. It is recommended to replace it once every two years. It can be used as a common spare part, and it can be purchased as a spare when choosing ELE Bead mill.

At present, ELE bead mills have users in many countries around the world, and after-sales teams are all over the world. The earliest used ELE sand mill has been in operation for 26 years and is still working today. In fact, there are not many wearing parts of ELE Bead mill, and the maintenance cost is also very low in the industry. The accessories are available from stock for many years, and the timeliness is guaranteed. When in use, as long as you refer to the manual for reasonable operation and timely maintenance work, contact ELE Company for repair in time if there is a failure, then your sand mill will always work normally.

What is the difference between nano bead mill and ordinary bead mill machine?

Nano bead mill are not actually developed in recent years. Nano bead mill appeared internationally as early as 2000. As an application of high-end technology, they play an important role in many fine chemicals and new materials,However, Until 2006 that nano bead mill were realized in China. In particular, the early domestic nano bead mill manufacturers represented by Shanghai ELE Company, under long-term R&D development and promotion, Only then has the nanometer sand mill been rapidly applied in a large number of domestic applications, and today it has been exported to the international market in large quantities.

At present, many users said that there seem to be many manufacturers of nano bead mills that can be find in China, but after purchasing and using them are not satisfactory. The problem lies in the fact that users know very little about nano bead mill. In fact, there are very few manufacturers on the market that have the real quality of nano-level ,This will be analyzed from the technical level of the nano bead mill, and then I will explain to you, what is the difference between the nano bead mill and the ordinary mill? At the same time, also talk about the key technical problems that the two cores of the nano bead mill are difficult to overcome.

First of all, from the actual fineness index of the material be grinding (on the basis of the mature and feasible technology of its own material formula). In a broad sense, a nano-bead mill can be called a nano bead mill if it can reach 1 micron or less, but in a strict sense, it needs to be 200 nanometers or less to be truly called a nano-bead mill. Although there is no relevant standard, there is such a consensus in the industry. In fact, it is intuitive and easy for users to use the fineness index to measure whether the nano bead mill is more intuitive and easy to accept, but because of the uncertainty of the material, the fineness index is actually not too scientific and not too accurate.

So, is there a measure of the equipment itself to judge whether it is a real nano bead mill? Of course there are, and there are many indicators. Here are two important indicators that are easy for users to accept.

The first is to look at the energy of the bead mill, which can be divided into two aspects: energy density and linear velocity . The use of high energy grinding does improve the fineness efficiency a lot, but the technical difficulty here is whether the material is durable or not. Yes, whether the processing accuracy can be achieved. Simply put, it is the motor power and the diameter of the grinding cavity. This index can identify the vast majority of fake nano bead mills on the market, especially some low-end pin type bead mills, which are also called "pseudo pin bead mills" in the industry. The cavity diameter is about the same size as a traditional disc bead mill)

The second is to see if the smallest grinding medium can be 0.1mm. In theory, the smaller the grinding media, the finer the grinding fineness. The technical difficulty here is that the smaller the medium, the higher and higher the requirements for mechanical seals. The mechanical seal of the 0.1mm small bead medium (ELE patent) and the seal used for the large bead medium are completely two-level seals. The level of technical content is much higher, and the two are not comparable. There is also the contradiction between the accuracy of the discharge separator and the size of the discharge area. The smaller the grinding media, the more precise the separator is. This is also the hard index of the nano bead mill and an important manifestation of the precision of the nano bead mill.

Finally, after understanding the above two points, when choosing a nano bead mill, it is recommended to go to the manufacturer for on-site inspection, mainly to look at the structure and processing process. The above two points are also very easy for users to intuitively judge. Basically, you can avoid choosing fake nano bead mill. Other indicators for measuring nano bead mills are not listed here. You can directly consult ELE sales engineers .

Why some pin type bead mill not as fine as the ELE pin type bead mill machine?

The emergence of the pin bead mill has completely changed the original traditional horizontal bead mill where the fineness can only be ground to the micron level. The most fundamental reason is to increase the energy input, so that the grinding kinetic energy in the grinding chamber is greater. The rotor commonly used in the original traditional horizontal bead mill is basically a disc structure. The mechanism of grinding mainly relies on the friction of the grinding disc to drive the beads. The impact force is small. The rotor structure of the pin bead mill is a rod and nail structure. The grinding mechanism mainly depends on the percussion force of the rod pin,The instantaneous impact force is extremely large, so that the grinding medium obtains huge kinetic energy. The medium collides with each other at high speed, friction and squeezes so that the material is quickly ground fine.

Of course, this is only an analysis from the difference in rotor structure. In fact, many bead mill counterparts only know one thing, but they do not know the other, and blindly imitate. Therefore, many manufacturers of "pseudo pin type bead mill" have appeared in the industry."pseudo pin type bead mil’’ is mostly just modified from the rotor structure on the basis of the original traditional disc bead mill. The original disc is simply converted into a rod pin structure, while the others are unchanged, just looking like rod-pin bead mill. But is not at all. The price is also much lower than the real pin type bead mill, but higher than the traditional disc type bead mill, and the use effect is naturally the same as that of the traditional disc type bead mill, which makes many users who have unknown reasons suffer fooled.

So many users will ask: "Why are some pin type bead mill not as fine as the ELE pin type bead mill?" Next, I will give a simple answer to this question. First of all, the kinetic energy and linear velocity should be large, which is manifested by the large motor power, large rotor diameter, and more wear-resistant materials. Secondly, the bead filling ratio is high and the bead is small, which is reflected in the design strength and precision of the machine, the more precise separation structure, and the more durable mechanical seal. This is the main reason why some pin type bead mill are not as fine as the ELE pin type bead mill. Detailed details can be further communicated with ELE sales engineer.

Bead Mill Vs Ball Mill

At present, the Bead mill and ball mill are two different types of equipment, but in fact there is a certain relationship between them, because the bead mill is developed from the basis of the ball mill, Both are using the grinding medium between the collision, extrusion, friction and other principles of crushing materials. But there are essential differences and applications between Bead mill and Ball mill.

I、Working principle

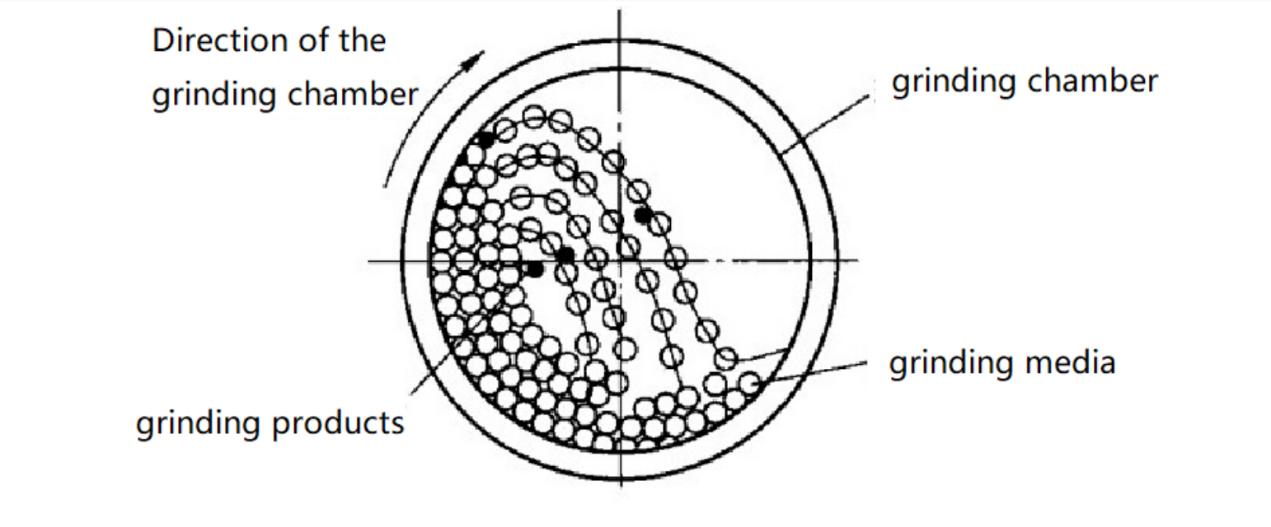

Ball mill: The cylinder rotates at a low speed, and there is no mixer in the cylinder. The large-scale grinding ball is used, and the gravity potential energy of the grinding ball is used to cut and crush the material. When the barrel of the ball mill rotates, the grinding body acts due to inertia and centrifugal force, and the frictional force acts on the cylinder liner to be carried away by the cylinder. When it is brought to a certain height, due to its own gravity And being thrown, the falling grinding body crushes the material in the cylinder like a projectile.

Ball mill Working principle

Bead Mill: The grinding chamber is fixed, there is a mixing shaft in different ways in the grinding chamber, using small grinding medium, adopting the agitator shaft imparts kinetic energy to the medium to break up the material. There are vertical or horizontal bead mill, disc and pin and turbine Type. The fineness of the grinding can reach 100 nm or 50 nm.

Bead Mill Working principle

II、Grinding Media Difference

Ball mill generally use steel balls and are loaded into the chamber according to different diameters and proportions. The grinding medium can also be used in steel sections. The size of the selected steel ball is generally large, usually 40mm, 60mm, etc.

Bead Mill: The grinding media of the bead mill generally uses zirconia beads, zirconium silicate beads or glass beads, which are selected according to different abrasive materials used by different manufacturers. ELE Bead mill adopt high wear-resistant alloy steel as the grinding material, its hardness can reach HRC62, so our company bead mill recommended 95% zirconia beads. Generally used size is 0.1mm~2.0mm

III、Application difference

The ball mill is the key equipment for crushing the material after it has been crushed. Ball mills are widely used in the production of cement, silicate products, new building materials, refractory materials, fertilizers, black and non-ferrous metal dressings and glass ceramics, dry or wet grinding of various ores and other grindable materials. It is very important to grind the ball mill in beneficiation.

Bead mill are mainly used for wet grinding of chemical liquid products (paints, inks, pigments, dyes, pesticides, paints, wood lacquers, automotive lacquers, nanomaterials, cell disruption, biomaterials, battery materials, titanium dioxide, alumina, For ceramic pastes and the like, the fineness is required to be 10 μm, about 5 μm, or nanometer.

The ball mill has a low rotation speed, a large media size, and a large radial velocity gradient along the pin. Therefore, the grinding efficiency is lower and the particle size distribution is wide. Therefore, the ball mill is gradually be replaced by the bead mill, and is now only used for hard Alloy, ferrite grinding or pre-grinding.

Therefore, when choosing, it is suitable time to use the high efficiency bead mill of Shanghai ELE